ALL RECIPES

7-Gallon Bourbon Mash Recipe (Classic Small-Batch Style)

7-Gallon Bourbon Mash Recipe (Classic Small-Batch Style)

Mash Bill:

- 78% corn

- 12% malted barley

- 10% malted rye

Yeast:

- Fleischmann’s All-Grain Yeast (or any quality distiller’s yeast)

1. Calculate Your Grain Amounts

For a 7-gallon mash, use a ratio of roughly 2 pounds of grain per gallon of water.

| Grain | Percentage | Weight |

|---|---|---|

| Corn | 78% | 10.9 lbs |

| Malted Barley | 12% | 1.7 lbs |

| Malted Rye | 10% | 1.4 lbs |

| Total Grain | 100% | 14 lbs |

2. Mashing Process

Step 1 — Heat & Add Corn:

- Heat 4 gallons of water to 190–200°F (88–93°C).

- Gradually stir in the cracked corn, ensuring there are no dry clumps.

- Maintain this temperature for 90 minutes, stirring often to avoid scorching.

This step gelatinizes the corn starch so it can later convert into sugar.

Step 2 — Add Malted Grains:

- Cool the mash to 150–160°F (65–71°C).

- Add malted barley and malted rye, which provide the enzymes needed for starch-to-sugar conversion.

Step 3 — Saccharification Rest:

- Keep the mash between 147–152°F (64–67°C) for 60–90 minutes.

- Stir occasionally.

- Test with iodine: if the test shows no black/blue color, starch conversion is complete.

Step 4 — Mash Out:

- Raise temperature to 170°F (77°C) for 10–20 minutes to halt enzyme activity and improve sugar extraction.

3. Fermentation

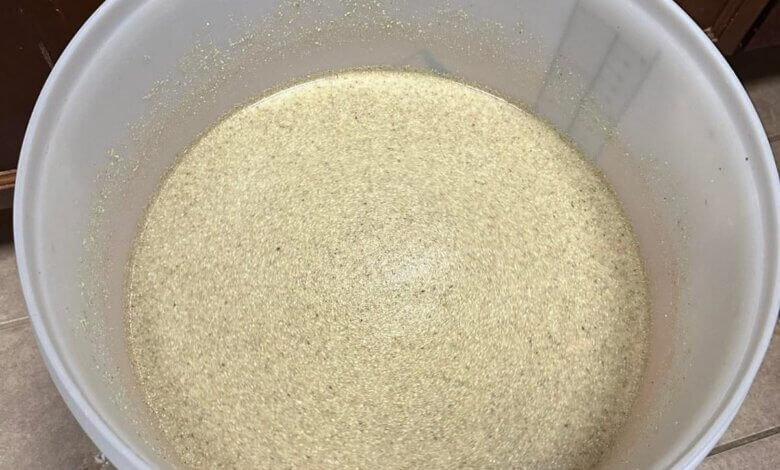

Step 1 — Cool & Transfer:

- Chill the mash to 70–77°F (21–25°C).

- Transfer into a sanitized fermenter.

Step 2 — Add Yeast (and Optional Backset):

- Pitch your yeast and add a yeast nutrient if desired.

- Optionally, add backset (liquid left from a previous distillation) at a ratio of 1:3 or 1:4 to stabilize pH and enhance flavor.

Step 3 — Ferment:

- Seal the fermenter with an airlock.

- Let it ferment for 5–7 days (or until bubbling slows).

- The mash should finish with a mildly sweet, sour aroma and an alcohol content around 8–10%.

4. Distillation & Aging

Step 1 — Distill:

- Run the fermented mash through a pot still or reflux still, discarding foreshots responsibly.

- Collect the distillate in stages to separate heads, hearts, and tails.

Step 2 — Age:

- Transfer the heart cut into new, charred American oak barrels.

- Age for at least 2 years to produce a straight bourbon, or longer for deeper caramel and vanilla notes.

Notes

- Temperature control and sanitation are key at every step.

- Experiment with yeast strains and aging times to develop your signature flavor.

- Label and store barrels in a cool, stable environment for optimal aging.